In a groundbreaking move that could redefine the future of electric vehicles, Elon Musk has officially launched Tesla’s long-awaited LFP battery “GigaFactory Delta,” located just outside Austin, Texas. This massive facility is now fully operational, with the capacity to produce enough batteries for up to 42 million vehicles, powering Tesla’s newest and most affordable model yet—the Tesla Model 2, set to start at an eye-popping $24,990. This marks a pivotal moment in Tesla’s mission to make electric mobility accessible to the masses.

For years, Musk has teased the idea of a truly affordable electric car that could rival gas-powered vehicles not just in performance, but in price. While skeptics questioned the feasibility and competitors scrambled to keep up, Tesla has now made it a reality. During a live-streamed event, Musk made a bold statement: “We’ve eliminated two-thirds of the global supply chain complexity by going all-in on LFP. This is what will make truly affordable EVs possible for every market—not just the luxury segment.”

At the heart of this revolution is Tesla’s adoption of lithium iron phosphate (LFP) battery technology. Unlike traditional nickel-based batteries, LFP batteries avoid costly and geopolitically sensitive materials like cobalt and nickel. They are cheaper to manufacture, more stable, safer, longer-lasting, and far easier to recycle. With GigaFactory Delta producing over 1.5 terawatt-hours of battery capacity annually, Tesla can power tens of millions of Model 2s over the next few years, transforming the economics of electric transportation.

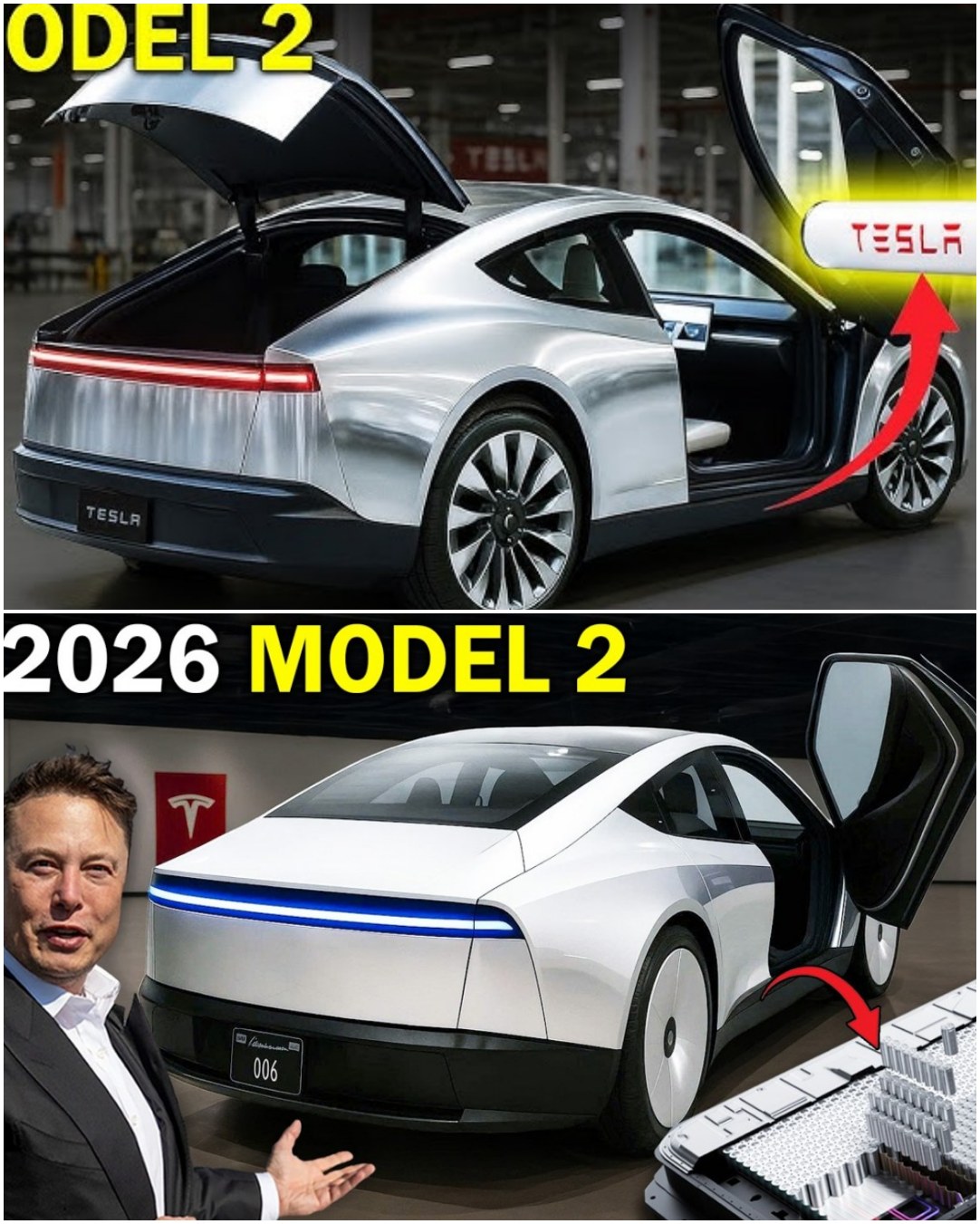

The Tesla Model 2, although still shrouded in secrecy, promises to deliver big on value. Expected to be a compact hatchback smaller than the Model 3, it’s optimized for mass production and affordability while still offering Tesla’s signature performance and innovation. Key features include a starting price of $24,990, a range of 250-300 miles per charge thanks to next-generation LFP cells, a minimalist cost-efficient interior, Tesla Vision-only autopilot technology, and built-in hardware for future autonomous robotaxi deployment. Musk’s ambitious plan is to produce at least 5 million Model 2 units per year by 2026, with GigaFactory Delta as the driving force behind this massive scale-up.

The switch to LFP batteries is more than a technical upgrade—it’s a strategic shift with global implications. LFP is cheaper, safer, more environmentally sustainable, and easier to recycle, removing the dependence on controversial mining practices. Tesla has already seen success with LFP-powered Model 3 and Model Y vehicles in China, proving that this battery chemistry can deliver real-world performance without compromise. Now, with large-scale LFP production in the U.S., Tesla is set to dominate not only the car market but also the energy storage sector, supplying Powerwall, Powerpack, and Megapack units for homes, businesses, and electrical grids.

The ripple effects of this move are seismic. While Chinese companies like BYD and CATL have pioneered LFP technology in Asia, Tesla is the first U.S. automaker to bring such large-scale production to North America. Analysts say this could crush the entry-level gas-powered car market, leaving legacy automakers like Ford, GM, and Volkswagen scrambling to compete on price and technology. Karen Zhou of EVThinkTank summed it up: “A sub-$25K EV with no compromises on safety or range is a market disruptor. If rivals can’t match Tesla’s cost structure and scale soon, they’ll be playing catch-up for years.”

But Tesla’s ambitions extend beyond just cars. GigaFactory Delta will also support Tesla’s energy division, producing batteries for Powerwall and Powerpack upgrades, expanding Megapack units to stabilize power grids, and building battery packs for Tesla’s upcoming robotaxi fleet expected to launch in select cities by 2026. This synergy between affordable electric vehicles and scalable energy solutions cements Tesla’s role at the crossroads of transportation and renewable energy.

Production at GigaFactory Delta is already underway, with the first Tesla Model 2 deliveries planned for late 2025 in the U.S., followed by Europe and Asia in early 2026. Tesla’s vertical integration—controlling everything from battery manufacturing to final vehicle assembly—gives the company a massive advantage in cutting costs and scaling production rapidly.

Of course, challenges remain. Producing millions of vehicles annually will test Tesla’s manufacturing limits, and the company must navigate regulatory hurdles, supply chain fluctuations, and growing competition. Yet, history shows Tesla thrives on pushing boundaries and shaking up established industries. The Model 2, backed by GigaFactory Delta’s LFP technology, may be Tesla’s most disruptive vehicle yet, democratizing EV ownership worldwide and accelerating the shift away from fossil fuels.

Elon Musk closed the launch event with a vision that goes beyond cars: “Affordable energy, affordable mobility—this is how we change the future. And the future starts now.” With GigaFactory Delta and the $24,990 Model 2, Tesla isn’t just building electric cars—it’s building the foundation for a cleaner, more sustainable world.